FELIX GLUER® : SINGLE

The most versatile model, ideal for any type of production.

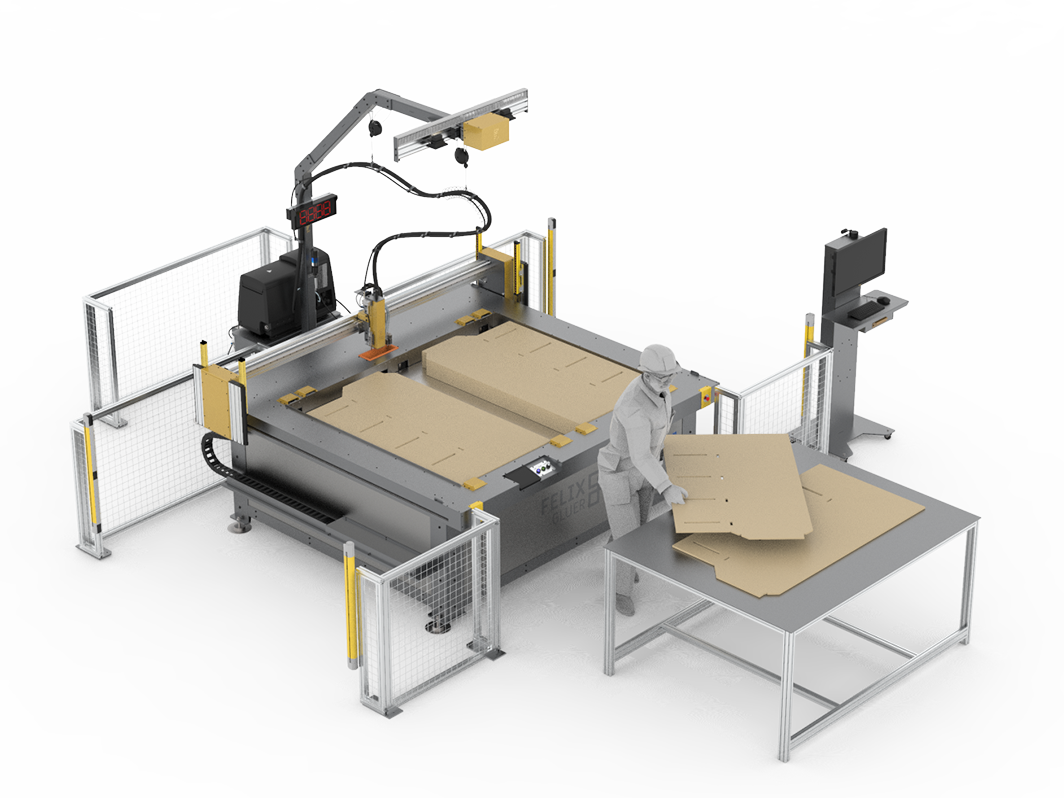

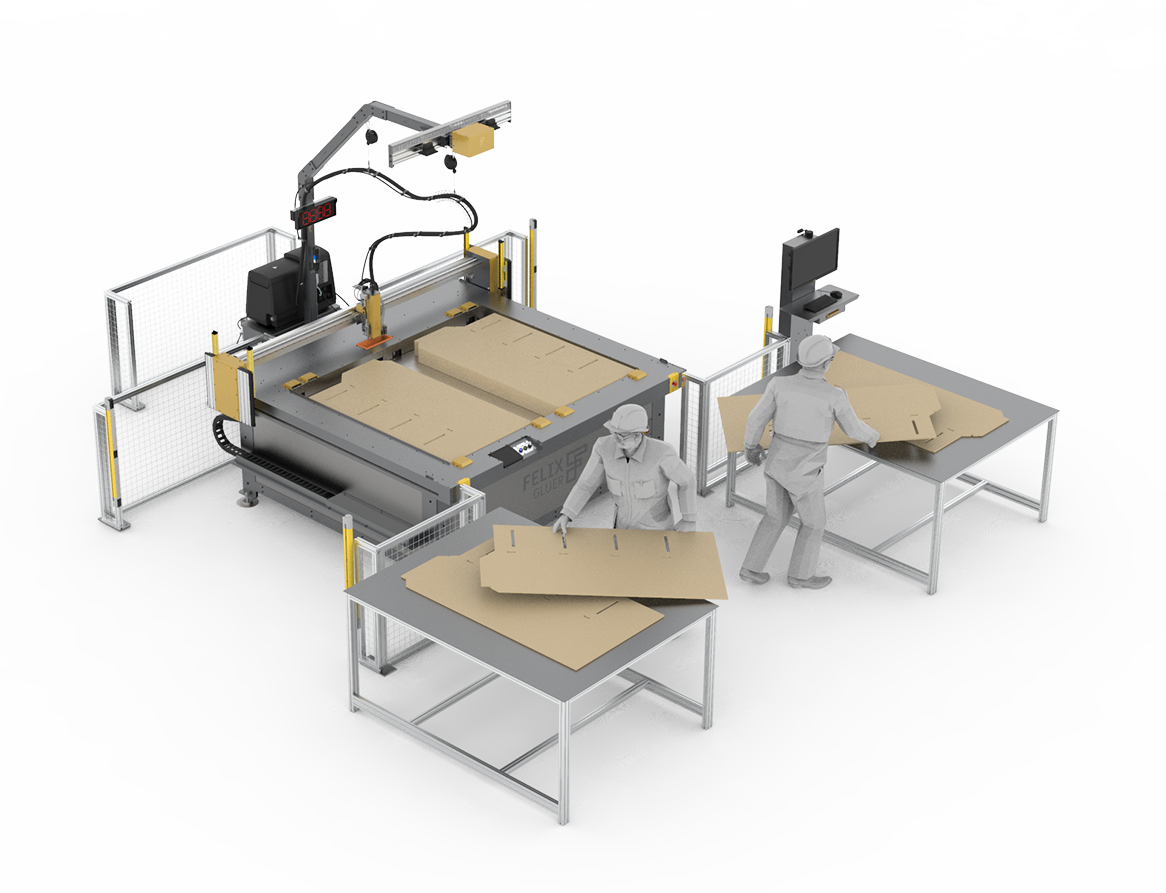

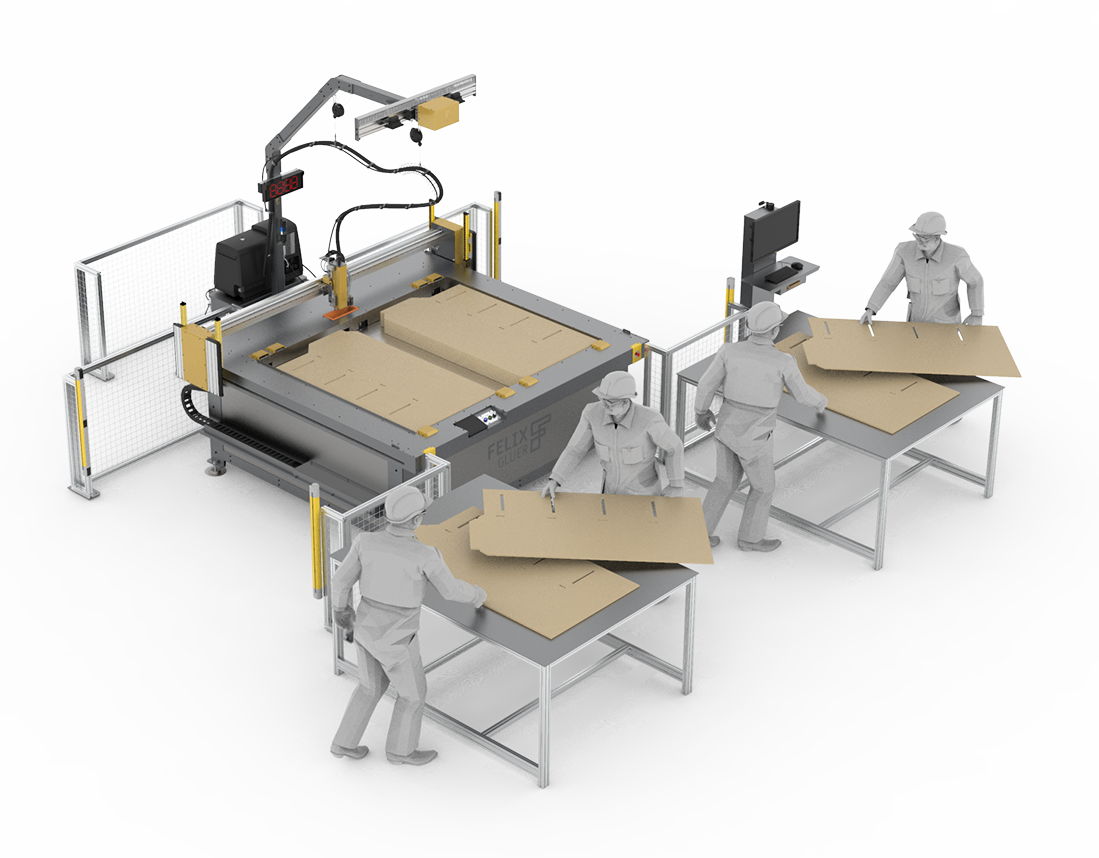

Flexible configuration options enable your team to customize workflow based on current operational needs. This model’s worktables are highly adaptable, allowing use by one, two, or four operators across various gluing setups. The two worktables can function independently or be combined into a single large gluing table. For enhanced safety, the machine is equipped with safety sensors, an optical safety barrier, and optional access limiters, providing comprehensive protection against potential safety risks.

Max single table load –

300 kg | Material stack height – 500 mm

The single worktable in this model supports a maximum load capacity of 300 kg, with glued elements stackable up to a height of 500 mm.

Features two independent stacking worktables with vertical movement and integrated safety sensors.

Semi-automatic material loading

The up-and-down stacking capability allows for seamless loading and unloading of glued elements. With vertical movement in both directions, worktables enable efficient material stacking. FELIX GLUER® : SINGLE comes in multiple sizes to accommodate all requirements.

Any gluing path possible

Experience the superior speed and accuracy of automated gluing. This digital system enables virtually any gluing design, from multiline patterns and dots to intricate spray paths. Efficiency is greatly improved with the option to apply both hot melt and cold glue simultaneously. A user-friendly plotter interface, combined with powerful design software, makes the gluing process simple and efficient.